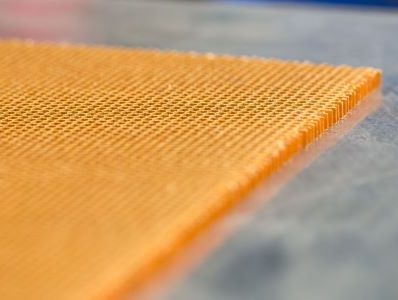

Quality Woven Fiberglass Prepregs

Axiom announces new website launch Jun 3rd

Axiom Materials formulates and manufactures prepreg utilizing resin systems including epoxy, phenolic, polyester, cyanate ester, polyimide and bismaleimide. Todays demanding operational environments require manufacturers have options for performance materials that meet their needs whether it is at -70°F to 900°F.

Download The Axiom Product Guide

In the demanding world of composite materials, performance is paramount. Whether you’re crafting aerospace components, marine structures, or high-end sporting goods, the quality of your prepreg directly impacts the final product. That’s where our premium woven fiberglass prepregs come in, offering an unparalleled combination of strength, durability, and processing efficiency.

Our woven fiberglass prepregs are meticulously engineered to deliver exceptional mechanical properties. The precisely woven fabric reinforcement, combined with our advanced resin systems, results in a material that boasts:

High Strength-to-Weight Ratio: Achieve remarkable structural integrity without sacrificing weight. Ideal for applications where lightweighting is crucial.

Excellent Dimensional Stability: Minimize warping and distortion, ensuring precise component dimensions and consistent performance.

Superior Impact Resistance: Withstand harsh environments and demanding applications, offering enhanced durability and longevity.

Controlled Resin Flow: Our prepregs are designed for optimal resin flow during curing, leading to uniform resin distribution and void minimization.

Customizable Resin Systems: Tailor the prepreg to your specific requirements with a range of resin systems, including epoxy, phenolic, and others, each offering unique performance characteristics.

Beyond performance, our woven fiberglass prepregs are designed to streamline your manufacturing process. The pre-impregnated nature of the material eliminates the need for messy resin mixing and wet lay-up, resulting in:

Reduced Labor Costs: Simplify your production process and minimize labor requirements.

Improved Consistency: Achieve consistent resin-to-fiber ratios, ensuring predictable and repeatable performance.

Reduced Waste: Minimize material waste and optimize resource utilization.

Faster Cure Cycles: Accelerate your production timeline with prepregs designed for efficient curing.

Enhanced Surface Finish: Achieve a smooth, high-quality surface finish, reducing the need for post-processing.

We are committed to providing our customers with high-quality woven fiberglass prepregs and exceptional service. Our team of experts is ready to assist you in selecting the right material for your specific application and provide technical support throughout the manufacturing process.

Elevate your composite manufacturing with our premium woven fiberglass prepregs. Contact us today to learn more about our products and how we can help you achieve your performance goals. We are dedicated to providing you with the materials and expertise you need to create exceptional composite products.

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-3100 | Toughened Low Dielectric Epoxy Fiberglass Prepreg | High transmission applications, radomes | Woven Prepreg, solution coated | Off-white on white | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853 |

| AX-3110 | Toughened, Flame Retardant Epoxy Fiberglass Prepreg | Flame retardant laminates, honeycomb and foam panels | Woven Prepreg (1 or 2-side coated) | Off-white on white | 250°F (121°C) | 180°F (82°C) | Meets FAR 25.853 |

| AX-3112T | High Toughness Flame Retardant Epoxy Fiberglass Prepreg | High toughness, flame retardant laminates, ducting, honeycomb panels, and foam panels | Woven Prepreg, solution coated | Off-white on white | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853. High Temp (HT) grade available |

| AX-3170 | Cyanate Ester Fiberglass Prepreg | High service temperature laminates with low dielectric constant & low dissipation factor | Woven Prepreg (1 or 2-side coated) | Clear on white | 260°F (127°C) | 700°F (371°C) | 700°F service achieved using 550°F post cure |

| AX-3180 | Low OSU /FST Epoxy Fiberglass Prepreg | Aircraft interior laminates & panels, A/C ducting | Woven Prepreg (1 or 2-side coated) | White on white | 250°F (121°C) | 250°F (121°C) | Meets 25.853 & FST / OSU. Snap Cure (SC) available. |

| AX-3201XL | Toughened Epoxy Fiberglass Laminating Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | Woven Prepreg (1 or 2-side coated) | Clear on white | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available. |

| AX-3206 | Toughened Epoxy Fiberglass Laminating Prepreg | High toughness laminates for prosthetics and race car industry | Woven Prepreg (1 or 2-side coated) | White on white | Variable | 250°F (121°C) | More toughened than AX-3201 series. |

| AX-3220 | High Temperature Epoxy Fiberglass Prepreg | High temperature laminates and high temperature ducting | Woven Prepreg (1 or 2-side coated) | Clear on white | 350°F (177°C) | 400°F (204°C) | Post cure recommended for peak performance. FR grade available. |

| AX-3260EL | Epoxy Fiberglass Tooling Prepreg | Low temperature cure, high temperature service tooling | Woven Prepreg (1 or 2-side coated) | Light amber on white | 125°F (52°C) initial, 380°F (193°C) final | 375°F (191°C) | Low temperature initial cure, then free-standing post cure to achieve Tg |

| AX-3270 | Structural Epoxy Fiberglass Prepreg | Structural composite components | Woven Prepreg (1 or 2-side coated) | Cream on white | 300°F (149°C) | 350°F (177°C) | Color variations available. Flame retardance available. |

"*" indicates required fields

CMC prepregs are used for parts requiring thermal performance up to 2200°F

Aerospace and Commercial Grade Nomex® Honeycomb to suit most aerospace and commercial applications.