Advanced Composite Products

Axiom announces new website launch Jun 3rd

Axiom Materials is the world’s largest producer of Oxide-Oxide Ceramic Matrix Composite pre-preg materials. Ox-Ox CMCs have significant application momentum as high temperature oxidation-sensitive components, particularly in the aerospace, hypersonics, and energy industries. We are leading the expansion of CMCs into new industrial applications in oil and gas refinery pipes, refractory ovens, and other high temperature products requiring a combination of high strength and longer lifecycles.

Specially formulated resin systems include epoxy, BMI, phenolic, polyester, cyanate ester, vinyl ester and polyimide.

Metal and composite bonding adhesives, surfacing and lightning strike films, and other bonding solutions.

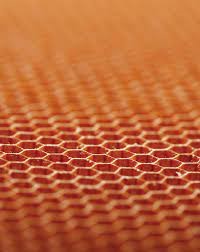

Axiom manufactures Aerospace and Commercial Grade Nomex® Honeycomb to suit most aerospace and commercial applications.

A variety of tooling prepregs, primers, adhesives, prepreg peel-plys, panel fillers, sealing resins are available.

"*" indicates required fields