Energy

Axiom announces new website launch Jun 3rd

Axiom materials manufacturing extends across the forefront of modern energy: power generation, lithium battery enclosures, hydrogen and natural gas pressure enclosures, refractory piping, and fracking bridge plugs. We are the largest global producer of Ox-Ox composites for solid oxide fuel cells and lithium battery enclosure, and we produce an extensive line of composites and adhesives for downhole applications. We are proud to apply the unique properties of our custom-tailored composites and films to help secure and advance the future of energy.

Axiom’s lightweight composites and oxide CMC materials deliver strength and chemical impermeability to power generation. Increasing efficiency and reducing electric component life cycle cost, Axiom’s materials are used in traditional energy production, and modern wind, solar, tidal, and fuel cell applications.

Petrochemical tubing manufactured with Axiom’s CMCs, prepregs, and resins resists both high temperatures and aggressive chemical attacks. Our CMCs are custom-tailored to support the high pressure, vibration, corrosive, and extreme temperature environments.

Our lightweight solutions resist thermal expansion at extreme temperatures and have made Axiom the leading global producer of Ox-Ox composites for solid oxide fuel cells.

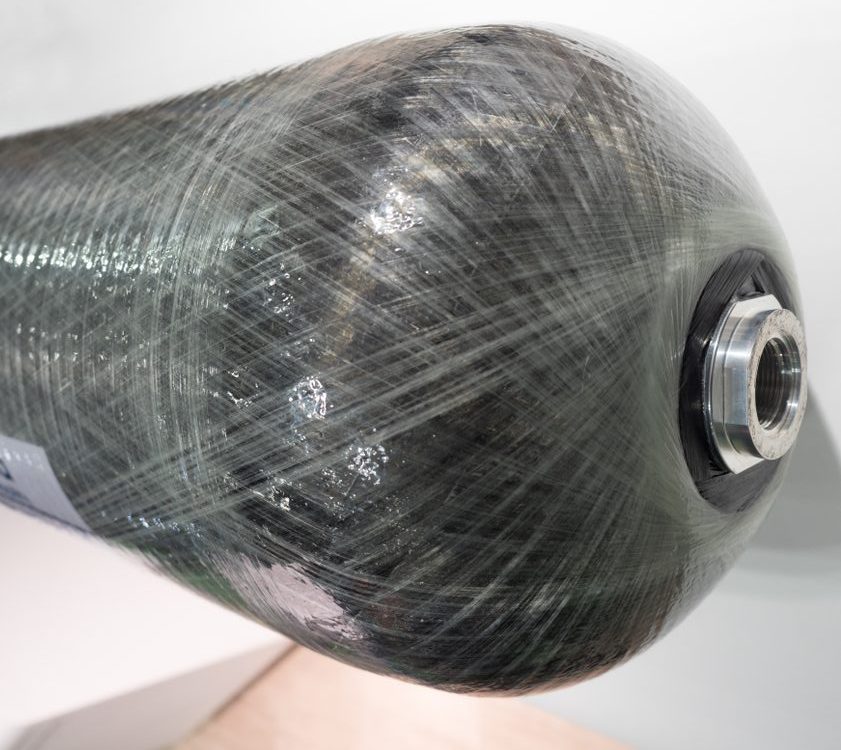

Hydrogen and natural gas pressure vessels are typically overlayed or wound with Axiom’s lightweight composites to achieve cost-effective, high-tensile strength protection. This increases longevity and ease of installation and repair.

"*" indicates required fields

Axiom’s CMCs control thermal runaway in lithium battery enclosures. Our composite materials are lightweight, resist vibration, and reduce noise in both aircraft and automobile applications. Axiom is the largest global producer of Ox-Ox composites for lithium battery enclosures.

Axiom CMCs excel in oil and gas burners not only because of their high temperature, high strength, corrosion resistance, but also because they are lightweight, vibration resistant, and noise muffling. These materials can be optimized for heat transfer or insulation, producing efficient, durable burners.

High-temperature industrial applications turn to Axiom Materials for high temperature, corrosion resistant, lightweight solutions that increase efficiency and service life. Axiom’s CMC surfacing films provide excellent finish and reduced porosity.

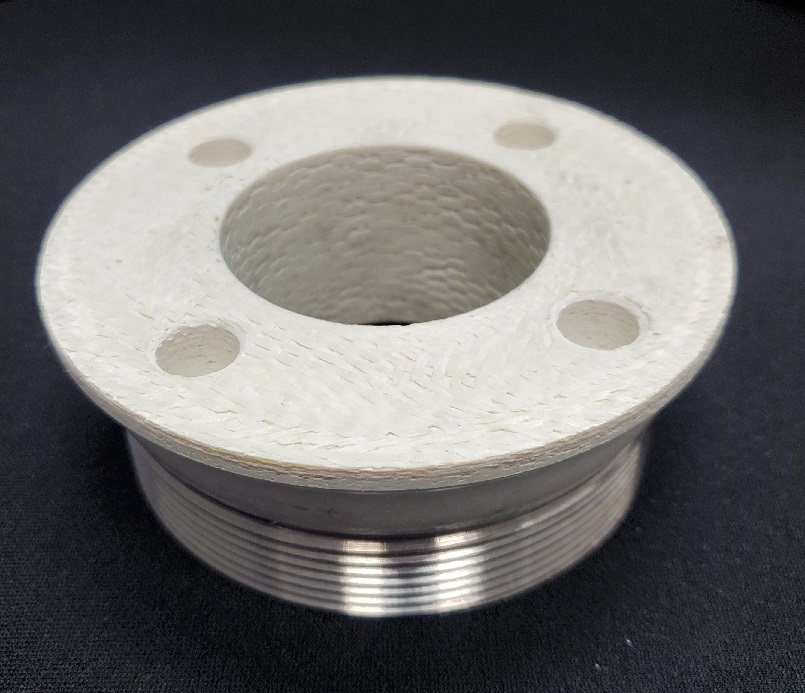

Frac plugs take advantage of Axiom’s composite materials for high-pressure resistance and chemical resistance to improve pump rates, and simultaneously remove more debris to save processing time and cost. These plugs are smaller, more compact, and designed with custom composite materials.