Industrial

Axiom announces new website launch Jun 3rd

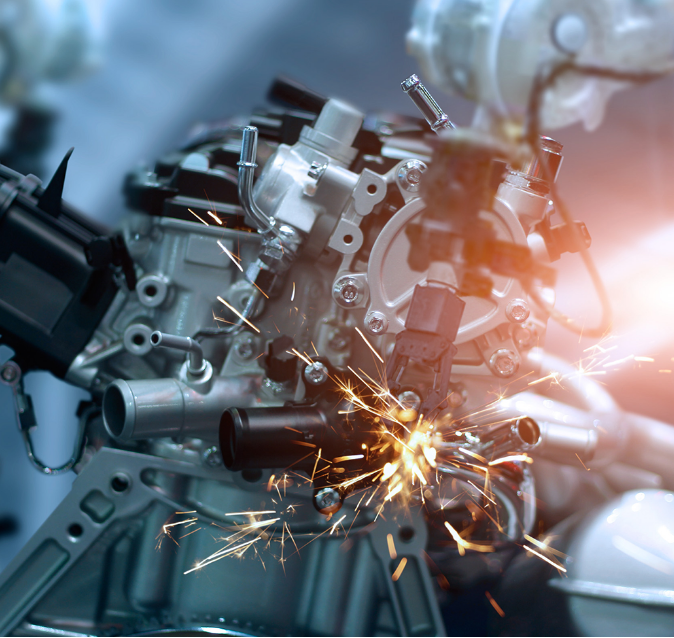

At the heart of modern industry, there are needs for very diverse materials that demand mechanical performance, high strength-to-weight ratios, chemical and corrosion resistance and can operate in both high and extreme temperature environments. Engineers choose Axiom’s lightweight, high-strength composites and adhesives for their performance and long-term operational benefits. With a history of extensive industrial production, from robotic arms to ceramic furnace composites, the quality of Axiom’s materials is matched by its unique capacity to provide cost-effective support to large volume projects.

From insulation to charging systems, to heating elements, Axiom’s CMC prepregs provide superior high temperature resistance and mechanical strength, along with a chemical/electrical inertness that resists corrosion, oxidation, flames, and leaching. The lightweight, highly variable designs also provide excellent thermal barriers between furnace hardware and exhaust components.

Axiom’s CMC prepregs provide steep temperature shielding gradients and long-term resistance to chemical attack. They are lightweight, strong, electrically insulating, non-porous, highly resistant to humidity, and can be incorporated with fire-retardant resins.

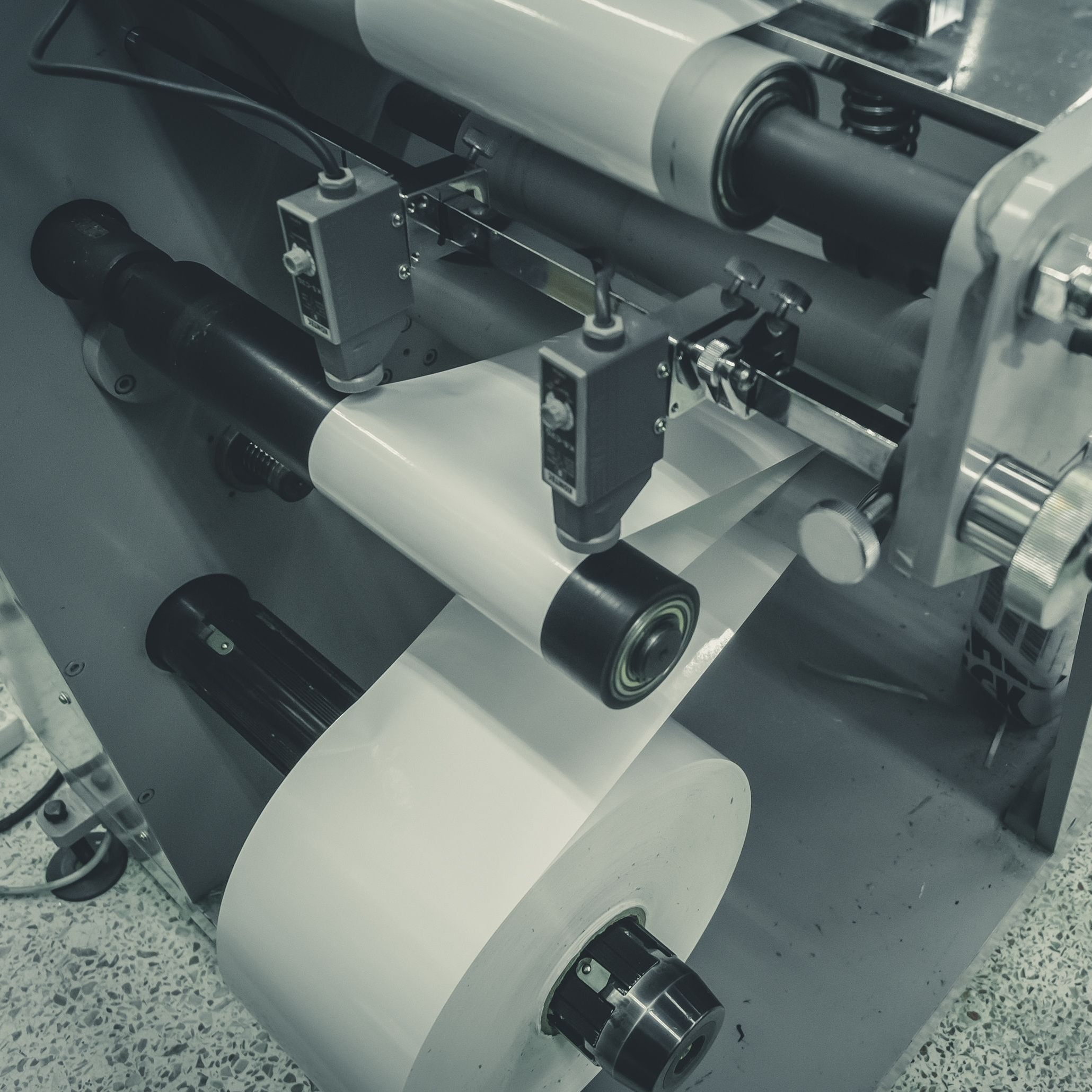

Rollers made with Axiom’s composites are up to 75% lighter than metals. They deliver high-speed, high stiffness-to-weight performance that decreases machine wear, increases roller efficiency, and extends service life on bushings and bearings.

"*" indicates required fields

Axiom’s lightweight composite materials support higher load capacities and are more resistant to vibration and deformation than steel or aluminum alternatives. Our materials are customized to meet operational constraints and conditions, and the result is increased production speed and fatigue life with reduced energy cost.

Gantries and lift arms manufactured from Axiom prepregs have higher torsional and bending stiffness, lower weight, and greater corrosion resistance that amplifies service life and saves on transportation costs. Design flexibility and material properties are tailored to meet both precision and heavy load applications.

Axiom Materials is the world’s largest industrial producer of Oxide-Oxide Ceramic Matrix Composite prepreg materials. Axiom has invested in fully automated process equipment and test labs to produce an array of CMC material types: