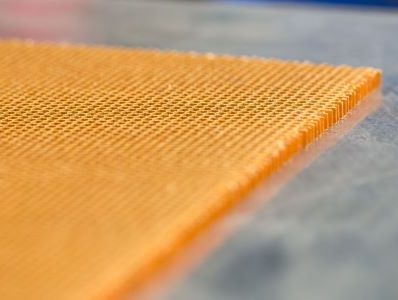

Quality Woven Aramid Prepregs

Axiom announces new website launch Jun 3rd

Axiom Materials formulates and manufactures prepreg utilizing resin systems including epoxy, phenolic, polyester, cyanate ester, polyimide and bismaleimide. Todays demanding operational environments require manufacturers have options for performance materials that meet their needs whether it is at -70°F to 900°F.

Download The Axiom Product Guide

Woven aramid prepregs are the ultimate choice for industries that demand superior strength, impact resistance, and lightweight performance. Engineered with precision, these advanced composite materials are pre-impregnated with a controlled resin system, ensuring consistent quality and optimized mechanical properties. Whether used in aerospace, defense, automotive, or sporting goods, woven aramid prepregs deliver exceptional reliability and durability in the most demanding applications.

Woven aramid prepregs consist of high-strength aramid fiber fabrics that have been pre-impregnated with a resin matrix, typically epoxy, phenolic, or thermoplastic resins. This process ensures uniform resin distribution and eliminates the need for additional resin application during manufacturing. Aramid fibers, such as Kevlar®, are renowned for their outstanding tensile strength, impact resistance, and heat resistance, making them an essential material for high-performance composites.

Superior Strength & Impact Resistance – Aramid fibers offer exceptional resistance to impact and abrasion, making them ideal for protective applications such as ballistic armor, helmets, and aerospace components.

Lightweight Performance – Compared to traditional materials, aramid prepregs provide high strength-to-weight ratios, reducing overall component weight without compromising durability.

Heat & Flame Resistance – Aramid materials maintain their structural integrity under high temperatures, making them suitable for aerospace and firefighting applications.

Fatigue & Vibration Resistance – The unique molecular structure of aramid fibers allows them to absorb vibrations and resist fatigue, enhancing longevity in demanding environments.

Corrosion & Chemical Resistance – Unlike metals, woven aramid prepregs are highly resistant to corrosion, making them ideal for marine, automotive, and industrial applications.

At Axiom, we are committed to providing our customers with the highest quality woven aramid prepregs. Our products are manufactured using state-of-the-art technology and adhere to stringent quality control standards. We offer a comprehensive range of prepregs to meet diverse application requirements, and our team of experts is available to provide technical support and guidance.

Unlock the potential of woven aramid prepregs and revolutionize your products. Contact us today to discuss your specific needs and discover how Axiom’s advanced materials can elevate your applications to new heights of performance and innovation. We provide tailored solutions to meet your specific needs. Let us help you achieve your goals with our premium woven aramid prepregs.

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-4110 | Toughened, Flame Retardant Epoxy Aramid Prepreg | Flame retardant laminates, honeycomb panels, and foam panels | Woven Prepreg (1 or 2-side coated) | Off-white on yellow | 250°F (121°C) | 180°F (82°C) | Meets FAR 25.853 |

| AX-4112T | High Performance, Toughened Epoxy Aramid Prepreg | High toughness, FR laminates, ducting, honeycomb panels, and foam panels | Woven Prepreg, solution coated | Off-white on yellow | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853 |

| AX-4151 | Modified PVB Phenolic Aramid Prepreg | High strength and impact-resistant bonding and laminating typically for ballistic applications | Woven Prepreg (1 or 2-side coated) | Off-white on yellow | 275°F (135°C) | 180°F (82°C) | Resin meets MIL-DTL-62474F |

| AX-4180 | Low OSU / FST Epoxy Aramid Prepreg | Aircraft interior laminates & panels, A/C ducting | Woven Prepreg (1or 2-side coated) | White on yellow | 250°F (121°C) | 250°F (121°C) | Meets FAR 25.853 & FST / OSU requirements |

| AX-4201XL | Toughened Epoxy Aramid Laminating Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | Woven Prepreg (1 or 2-side coated) | Clear on yellow | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available |

| AX-4220 | High Temperature Epoxy Laminating Aramid Prepreg | High temperature laminates and high temperature ducting | Woven Prepreg (1 or 2-side coated) | Clear on yellow | 350°F (177°C) | 400°F (204°C) | Post cure recommended for peak performance. FR grade available. |

| AX-4270 | Structural Epoxy Aramid Prepreg | Structural composite components | Woven Prepreg (1 or 2-side coated) | Cream on yellow | 300°F (149°C) | 350°F (177°C) | Color variations available. Flame retardance available. |

| AX-4300 | High Temperature Phenolic Laminating Aramid Prepreg | Ballistic panels, high temperature laminates | Woven Prepreg, solution coated | Amber on yellow | 300°F (149°C) | 500°F (260°C) | Resin meets MIL-R-9299C |

| AX-4500 | Toughened Phenolic Aramid Prepreg, Self-Adhesive | Honeycomb panels for aircraft interior components | Woven Prepreg, solution coated | Amber on yellow | 275°F (135°C) | 250°F (121°C) | Press grade and layup grade available |

"*" indicates required fields

CMC prepregs are used for parts requiring thermal performance up to 2200°F

Aerospace and Commercial Grade Nomex® Honeycomb to suit most aerospace and commercial applications.