Global Leader in Ceramic Matrix Composite Materials

Axiom announces new website launch Jun 3rd

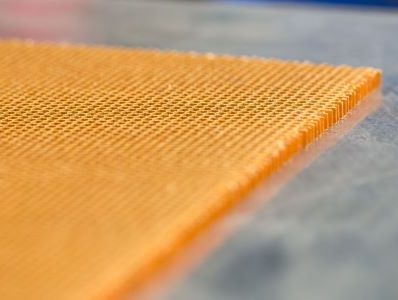

Axiom Materials is the world’s largest industrial-scale producer of Oxide-Oxide Ceramic Matrix Composite pre-preg materials. The company is expanding its CMC portfolio to serve secular growth in Aerospace, Hypersonics, Electric Vehicles, Air Mobility, Refractories, and Green Energy Production.

Axiom Materials operates its High-Temperature Composites Center in Santa Ana, California, USA. The company produces a state-of-the-art family of Oxide-Oxide CMC materials for high temperature continuous use applications in the range of 1400°F – 2200°F (760°C – 1200°C). Axiom is enhancing its current product line with the addition of C-SiC, and SiC-SiC proprietary materials for higher temperature continuous use applications up to 2700°F (1485°C). Axiom also produces a carbon-carbon phenolic precursor with operating temperatures up to 5000°F (2760°C).

Axiom has invested heavily in advanced process equipment and test labs to develop and produce an array of CMC material types:

The CMC materials may be processed via conventional layup and curing techniques, followed by free-standing high temperature sinter cycles to produce components for operation in extreme environments requiring a combination of high temperature resistance and fracture toughness. Target applications include advanced aircraft engines, hypersonics, space vehicles, lithium battery containment, oil and gas piping, petrochemical tubing, nuclear reactors, and refinery furnaces & kilns.

Axiom’s innovations in material science, process improvements, and technical leadership are contributing to the broader use of Ceramic Matrix Composite materials.

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-7800-610 | Water-based Ceramic Matrix Composite (CMC) Prepreg, High-strength | Aircraft engine components, ducting, oil & gas tubing, advanced energy, motorsports | Woven prepreg | White on white | 2500°F (1370°C) | 1600°F (870°C) | High temperature structural applications, solvent-free ceramic matrix |

| AX-7810-610 | Solvent-based Ceramic Matrix Composite (CMC) Prepreg, High-strength | Aircraft engine components, ducting, oil & gas tubing, advanced energy, motorsports | Woven prepreg | White on white | 2500°F (1370°C) | 1600°F (870°C) | High temperature structural applications |

| AX-7820-610 | 100% Aluminum Oxide Water-based Ceramic Matrix Composite (CMC) Prepreg, High-strength | Aircraft engine components, ducting, oil & gas tubing, advanced energy, motorsports | Woven prepreg | White on white | 2500°F (1370°C) | 1600°F (870°C) | High temperature Structural applications, solvent-free ceramic matrix |

| AX-7900-720 | Solvent-based Ceramic Matrix Composite (CMC) Prepreg, Low Creep/ High Temperature | Aircraft engine components, ducting, oil & gas tubing, advanced energy, motorsports | Woven prepreg | White on white | 2500°F (1370°C) | 2100°F (1150°C) | Low creep, low dielectric, higher temperature applications |

| AX-7900-312 | Solvent-based Ceramic Matrix Composite (CMC) Prepreg, Low Dielectric | Thermal/fire barriers, exhaust components, refractory, furnace hardware, insulation, RF transparent radomes | Woven prepreg | White on white | 1800°F (982°C) | 1472°F (800°C) | Low cost, low dielectric, insulation or flame barrier applications |

| CerFace™ AX-8900 | Oxide ceramic-based surfacing film reinforced with alumina-mullite paper carrier | High-temperature parts for industrial, power generation, and aero engines applications, combustors, turbine vanes, shrouds, mixers, gas filters, and furnace hardware | 24”wide film, .008” thickness | White | 2500°F (1370°C) | 2100°F (1150°C) | Product is engineered to co-cure with AX-7900 Ox-Ox prepreg to improve surface finish |

| CerFace™ AX-8810 | Oxide ceramic-based surfacing film reinforced with alumina paper carrier | High-temperature parts for industrial, power generation, and aero engines applications, combustors, turbine vanes, shrouds, mixers, gas filters, and furnace hardware | 24” wide film, .008” thickness | White | 2500°F (1370°C) | 1600°F (870°C) | Product is engineered to co-cure with AX-7810 Ox-Ox prepreg to improve surface finish |

"*" indicates required fields

Specially formulated resin systems include epoxy, phenolic, polyester, cyanate ester, vinyl ester and polyimide.

Aerospace and Commercial Grade Nomex® Honeycomb to suit most aerospace and commercial applications.