Quality Unidirectional Prepregs

Axiom announces new website launch Jun 3rd

Axiom Materials formulates and manufactures prepreg utilizing resin systems including epoxy, phenolic, polyester, cyanate ester, polyimide and bismaleimide. Todays demanding operational environments require manufacturers have options for performance materials that meet their needs whether it is at -70°F to 900°F.

Download The Axiom Product Guide

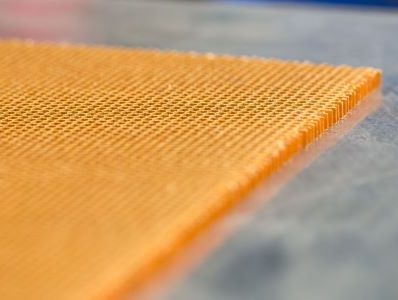

In the relentless pursuit of lightweight, high-strength materials, advanced industries are turning to unidirectional (UD) prepregs. Engineered for precision and performance, UD prepregs offer a transformative solution for applications demanding exceptional mechanical properties and structural integrity.

Unidirectional prepregs consist of continuous reinforcing fibers, such as carbon, glass, or aramid, aligned in a single direction and pre-impregnated with a resin matrix. This precise fiber alignment maximizes the material’s strength and stiffness along the fiber direction, offering unparalleled load-bearing capabilities. Unlike woven fabrics, which distribute strength in multiple directions, UD prepregs deliver focused, targeted performance.

Superior Mechanical Properties: The aligned fibers provide exceptional tensile strength and stiffness in the fiber direction, enabling the creation of lightweight structures with remarkable load-bearing capacity.

Tailored Performance: By strategically layering UD prepregs with varying fiber orientations, engineers can precisely control the mechanical properties of a composite structure, optimizing performance for specific applications.

Reduced Weight: The high strength-to-weight ratio of UD prepregs allows for significant weight reduction compared to traditional materials, enhancing efficiency and performance.

Enhanced Design Flexibility: UD prepregs can be easily cut and shaped, enabling the creation of complex geometries and optimized structural designs.

Consistent Quality: The controlled pre-impregnation process ensures uniform resin distribution and fiber alignment, resulting in consistent material properties and predictable performance.

Improved Fatigue Resistance: The continuous fibers and strong resin matrix contribute to excellent fatigue resistance, extending the lifespan of critical components.

We are a leading provider of high-quality unidirectional prepregs, offering a comprehensive range of materials and expertise to meet your specific needs. Our commitment to innovation and quality ensures that you receive the most advanced and reliable solutions for your applications.

Extensive Product Portfolio: We offer a wide selection of UD prepregs with various fiber types, resin systems, and areal weights.

Customized Solutions: Our experienced team can work with you to develop custom UD prepreg solutions tailored to your specific requirements.

Technical Expertise: We provide expert technical support and guidance throughout the design and manufacturing process.

Quality Assurance: We adhere to stringent quality control standards to ensure the consistency and reliability of our products.

Global Reach: We serve customers worldwide, providing timely and efficient delivery.

Unlock the full potential of your designs with our high-performance unidirectional prepregs. Contact us today to learn more about how we can help you achieve your performance goals.

| Product | Description | Applications | Form | Matrix Color | Max. Short Term Use Temp, °F (°C) | Max. Continuous Operating Temp, °F (°C) | Comments |

|---|---|---|---|---|---|---|---|

| AX-6111 | General Purpose Flame Retardant Epoxy Unidirectional Prepreg | Aircraft flooring, high-rise flooring, cargo liners, high impact surfaces, UAVs, sporting goods | UD prepreg (2-side coated) | Off-white | 250°F (121°C) | 200°F (93°C) | Meets FAR 25.853. |

| AX-6180 | Low FST/OSU Epoxy Unidirectional Prepreg | Aircraft interior components, seatbacks, doublers | UD prepreg (2-side coated) | White | 250°F (121°C) | 250°F (121°C) | Meets FAR 25.853 & FST / OSU requirements |

| AX-6200 | Toughened, High Clarity Epoxy Unidirectional Prepreg | Performance sporting goods, automotive parts & components | UD prepreg (2-side coated) | Clear or light black | 250°F (121°C) | 250°F (121°C) | General purpose |

| AX-6201XL | Toughened Epoxy Unidirectional Prepreg Extra-long Outlife | High strength laminates requiring good structural properties and/or high clarity | UD prepreg (2-side coated) | Clear or light black | Variable | 250°F (121°C) | Flame Retardant (XL/FR) variant available |

| AX-6270 | Structural Epoxy Unidirectional Prepreg | Structural composite components | UD prepreg (2-side coated) | Cream | 300°F (149°C) | 350°F (177°C) | Color variations available. Flame retardance available. |

"*" indicates required fields

CMC prepregs are used for parts requiring thermal performance up to 2200°F

Aerospace and Commercial Grade Nomex® Honeycomb to suit most aerospace and commercial applications.